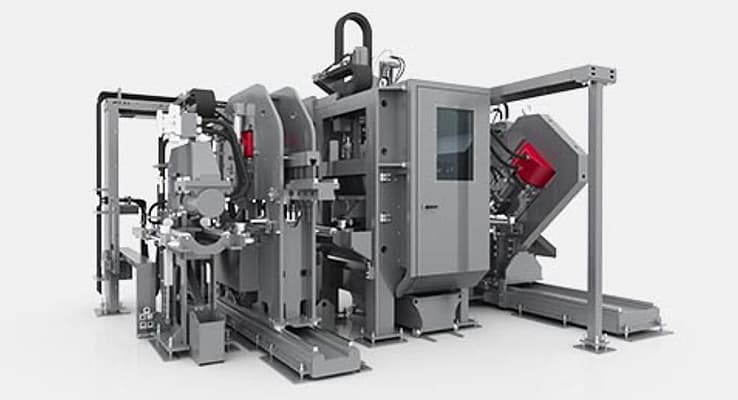

Structural Fabrication Machine Welding

Gulf States Saw & Machine Company also can fulfill Machine Parts orders. You only need to fill out a form. Within minutes, you will be contacted by a Parts Representative.

Gulf States Saw & Machine Co., Inc. holds the largest southeast saw-blade workshop. Our supply list contains over 50,000 items that we are able to offer our customers. Our clients are as important as our huge sales. We make it a priority that they are taken care of 24/7, 365.

Gulf States Saw & Machine Co., Inc. has developed one of the best reputations in the metal fabrication machinery industry. Gulf States Saw & Machine Company is the largest Distributor of Metal Fabrication & Robotic Welding in the South. Committed to delivering the latest in technology and high-quality service for over 30 years.

Gulf States Saw & Machine Company also can fulfill Machine Parts orders. You only need to fill out a form. Within minutes, you will be contacted by a Parts Representative.

Gulf States Saw & Machine Co., Inc. is a supplier of professional fabrication equipment to professional fabators since 1992. Hueytown, the heart of our operations, is where we are based. The hub of operations allows us to seamlessly serve the ten states. Gulf States Saw & Machine Co., Inc., a sister organization to Alabama Tool & Supply Co., Inc., established in 1979. We are a family owned and managed business.

Our core business is robotic welding. Capital Robotics has its headquarters in Atlanta. However, there is also a Dallas branch that maintains systems and offers training to customers. Capital Robotics continues to grow its technical workforce, including welders and service engineers.

Gulf States Saw & Machine Co., Inc. is the Southeast's largest sawblade shop and provides over 50,000 products through its supply catalogue. Our philosophy is to take care of our customers 24 hours a days, 365 days.

Thanks to years of experience in a wide array of industries and with a wide range of technology, we know how to help everyone from small job shops to large international brands utilize the latest equipment and technology. So no matter what type of machine you�re looking for, we can help design, specify, install and service just about any type of metal fabrication equipment.

And while different metal fabrication companies use different techniques, most rely on three basic processes: cutting, bending and assembling.

Structural fabrication refers to the cutting, bending, and assembling of steel to create different products.

Structural steel fabrication involves cutting, bending and welding steel to make a structure. Unlike various types of welding in which steel alloy is repaired or strengthened, steel fabrication is when pieces of steel are put together to form different structures that are usually of predefined sizes and shapes.